Leak Detection System

Leak Detection System

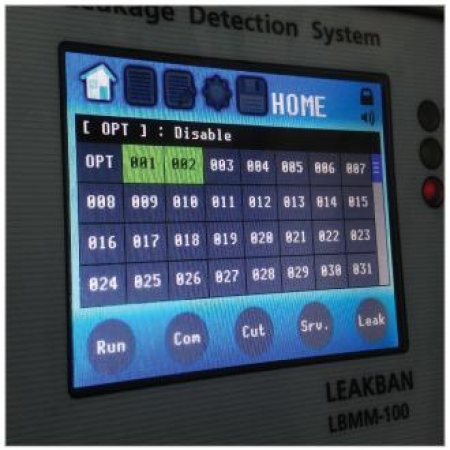

LBMM-100 Master Module Monitoring and Alarm

LBMM-100 is the main monitoring unit for the leak detection system and it works with sub-modules and sensing cables.

Product Features

When detecting any event with a LBSM in slave mode, it produces a visual and auditory alarm to be noticed from distance with ease. Furthermore, all the data, which is safely stored in the provided external SD-Card, can be read by a personal computer even in the case the product is no longer functional. When the LBMM is working in slave mode, it performs the same functions as the LBSM, sub-module does.

Product Specification

| Content | LBMM-100 |

|---|---|

| Power Supply | AC 110 ~250V /50, 60Hz (DC SMPS Built in) |

| Functions | Leak detection and positioning / Contamination check of sensing cable / Continuity check of sensing cable |

| Display/Alarm | 3.5 inch TFT-LCD / Built in |

| Sensing Time | Max. 8 seconds (default) |

| Sensing Length | Max. 1,000m / 1m accuracy |

| Operating Temp / Humidity | -10~85℃ / 30~80% RH |

| Output | Replay - 3 Channels (AC 250 - 10A, 30Vdc - 10A) Analog Output; 1 Channel (0 - 20mA) 1 Channel (0 - 10Vdc) |

| RTC Battery / Memory | Built in / SD-CARD |

| Parameter Setting | KEY & Modbus RTU |

| Communication Method RS | RS485 - 2wire |

| Protoco | Modbus RTU |

| Communication Distance / Number of Multi-Drop | 1.2Km / 32 |

| Data Transferring Speed | 9600BPS |

| Data bit / Stop bit / Parity bit | 8bit / 1bit / none(Fixed) |

| Housing | Steel |

LBSM-200,300 Sub Module Leak Detection and Alarm Device

LBSM-200 and LBSM-300 are sub-modules for LeakBan leak detection system and they generally work with the LBMM, master-module unit and a leak sensing cable

Product Features

When leak sensing cables detect any event ,the LBSM sends pre-determined signals to the LBMM and at the same time they produce a visual and auditory alarm. Being determined as master module, the LBMM device should be linked with LBSM200 or LBSM300via RS485 communication protocol for monitoring and alarming all the events and for showing the status of leak sensing cables on the LCD screen. All technical parameters and event-related data are automatically saved and stored in the provided external SD-card of the LBMM device and then can be read by PC or other electronic devices. LBSM can pinpoint the place where the leakage occurs with high accuracy. The housing of LBSM-200 and 300 is constructed with flame retardant PC and provides IP54 ingress protection.

It can be mounted inside an enclosure by DIN rail or wall-mounted by the provided fixing screws. The LBSM-200 features a 1.4inch LCD display and one LED light while LBSM-300 has no LCD display

Product Specification

| Content | LBSM-200 / LBSM-300 |

|---|---|

| Power Supply | DC 10 ~30Vdc / 1.5W |

| Functions | Leak detection and positioning / Contamination check of sensing cable / Continuity check of sensing cable |

| Display/Alarm | 1.4 inch LCD & LED / ALARM (LBSM-200) LED / ALARM (LBSM-300) |

| Event Replay | 1 Channel A, C Point of Contact - (24Vdc - 1A, 250VAC-0.5A) |

| Sensing Time | Max. 8 seconds (default) |

| Sensing Length | Max. 500m / 1m accuracy |

| Operating Temp / Humidity | -10~85℃ / 30~80% RH |

| Mounting Method | DIN rail or panel hole attachment |

LBSC-1000 Water Sensing Cable

The LEAKBAN LBSC-1000 sensing cable can accurately detect the leakage point, so it is installed with the

LBMM master module and LBSM sub-module to detect leakage quickly, and when a notification signal is

received to LBMM through the LBSM's RS485 communication protocol, LBMM and LBSM generate an

alarm and locate the leak point.

Use

- data centre sub-floor

- telecommunication centre

- HVAC equipment

- insulated pipelines

- electrical vaults

- storage areas

- roof or bathroom

Characteristics

- Conforms with EMI/EMC and

- Electrical Safety requirements

- Sensing cable can be extended up to 1km

- Fast response (default 8 seconds)

- Leak Point Accuracy (± 1m /1,000m)

- Resistance to abrasion, chemicals

- Standard supply 3.5m, 7m, 15m

- Operating temp. -40℃ ~ 80℃

LBSC-3000 Acid Sensing Cable

LEAKBAN LBSC-3000 sensing cable can accurately detect the leakage points of sulphuric/sulphurous acid, hydrochloric acid and PAC. If it is installed with LBMM master module and LBSM sub-module to detect leakage quickly and receive notification signal to LBMM through LBSM's RS485 communication protocol, LBMM and LBSM generate alarm and locate leak point.

Use

- semi-conductor factory

- battery factory

- display panel (LCD/LED) factory

- all other chemical plants

- Applicable chemical : sulphuric acid,

- hydrochloric acid, nitric acid, and PAC etc

Characteristics

- Conforms with EMI/EMC and

- Electrical Safety requirements

- Sensing cables can be extended up to 1km

- Fast response less than 15 minutes (depending on the acid type)

- Leak positioning accuracy (± 1m /1,000m)

- Resistance to abrasion, chemicals

- Standard supply 3.5m, 7m, 15m

LBSC-7000 Multi-Purpose Sensing Cable

The LEAKBAN LBSC-3000 sensing cable can accurately detect the leakage point for various conductive liquids such as acid, acid-based materials and water.

If it is installed with LBMM master module and LBSM sub-module to detect leakage quickly and receive notification signal to LBMM through LBSM's RS485 communication protocol, LBMM and LBSM generate alarm and locate leak point.

Use

- semi-conductor factory

- battery factory

- display panel (LCD/LED) factory

- all other chemical plants

- Applicable chemical : sulphuric acid, hydrochloric acid, nitric acid, and PAC etc.

- sodium hydroxide, water

Characteristics

- Conforms with EMI/EMC and

- Electrical Safety requirements

- Sensing cables can be extended up to 1km

- Fast response Max. 8seconds (depending on liquid type)

- Leak positioning accuracy (± 1m /1,000m)

- Resistance to abrasion, chemicals

- Standard supply 3.5m, 7m, 15m

- Operating temp. -40℃ ~ 80℃